Toda Racing Heavy Duty Timing Chain F20/F22C 14401-F20-000 IN STOCK!

In Stock and Ready to Ship!

Toda Racing Heavy Duty Timing Chain F20C/F22C. Fits all S2000 00-09 F20C/F22C Engines.

With the extra stress placed on the valve train as a result of using upgraded camshafts, and valve springs, improved timing chain strength becomes very important. Advanced punch manufacturing techniques used in the making of the TODA Heavy Duty Timing Chain have improved accuracy and reduced edge burrs leading to reduced friction and smoother chain operations. Areas such as a larger plate shape enabled the use of a larger diameter pin, which helps reduce chain stretching under constant high velocity revolutions by as much as 35%.

Please reference the application table below to determine which Timing Chain is compatible with your vehicle.

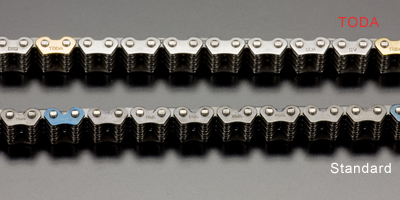

Timing Chain back face

Advanced punch manufacturing techniques used in the making of the TODA Heavy Duty Timing Chain, have improved accuracy and reduced edge burrs leading to reduced friction and smoother chain operations.

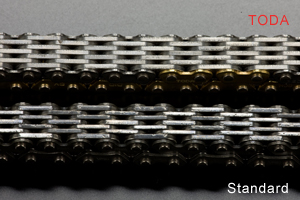

Timing Chain side face close-up

With improved accuracy, small but important improvements to the design of the TODA Heavy Duty Timing Chain have been possible. Areas such as a larger plate shape and larger pin diameter have helped to improve the chains strength and to reduce chain stretch.

Up until now, tuning specialists have had to use the standard timing chain. Now there is a product that after reviewing the design and detailed modifying has gained improved accuracy and durability. This is TODA Racing's Heavy Duty Timing Chain. With the extra demand of hi-performance driving even with the standard road engine and/or components such as camshafts that place extra stress on the valve train system, improved chain strength is important.

The highly precise side plates reduce friction and improve the revolution fatigue strength by increasing the area of the plates, a reduction in the burrs and the finish to each individual plate. Moreover, due to the higher precision of manufacture, the hole size and shape in the plate have enabled the use of a larger diameter pin, this also contributes to reducing the stretching of the chain under constant high velocity revolutions by as much as 35%. (From Manufactures data)